Create better outcomes for dental labs and manufacturers through connected design & manufacturing optimization & automation in a cloud-native platform.

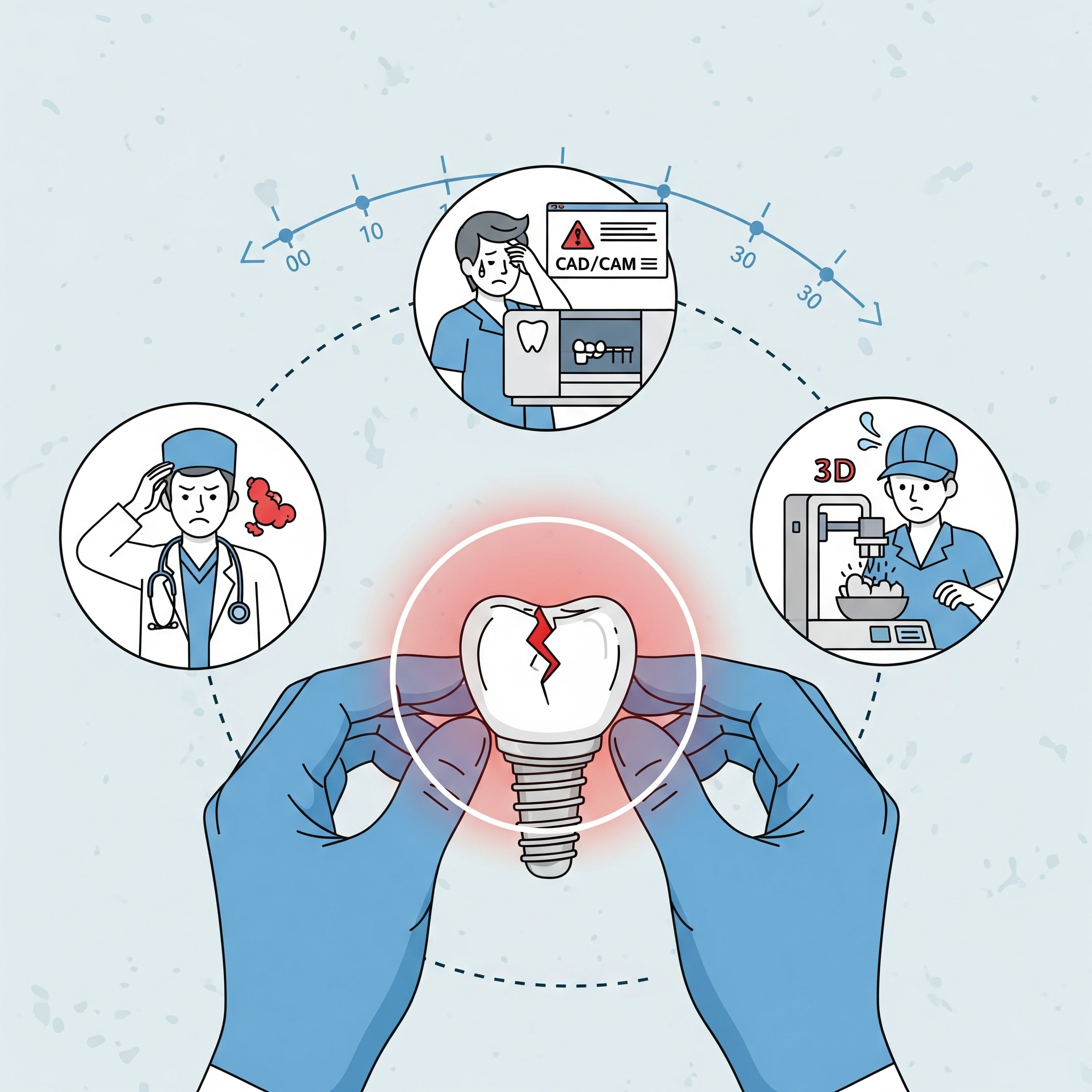

Dental labs frequently create and submit designs to manufacturing with critical flaws, leading to production failures, wasted time and material, and extended lead times. This impact is felt by the dentist, the lab, and the manufacturer.

Not CAD vs CAM — DentSolv is the manufacturing firewall between lab creativity and manufacturing reality.

Deterministic geometry checks and constraint enforcement (product spec, machine limits, material/process limits), with automated validation/reporting so issues are caught before they hit production.

Geometry repair/optimization for mesh artifacts, undercuts, smoothing, manufacturability, and margin (band) + body thickness corrections—plus geometry sectioning for precise downstream control and repeatability.

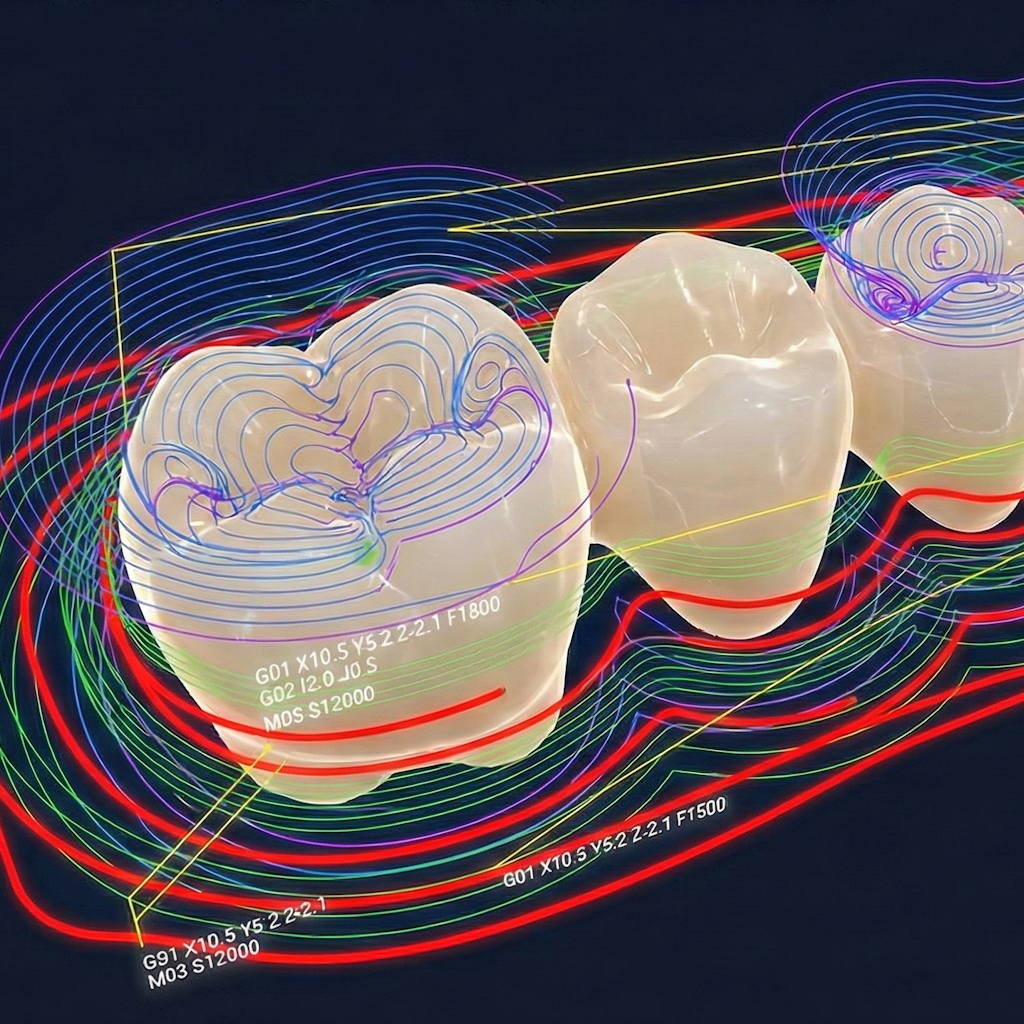

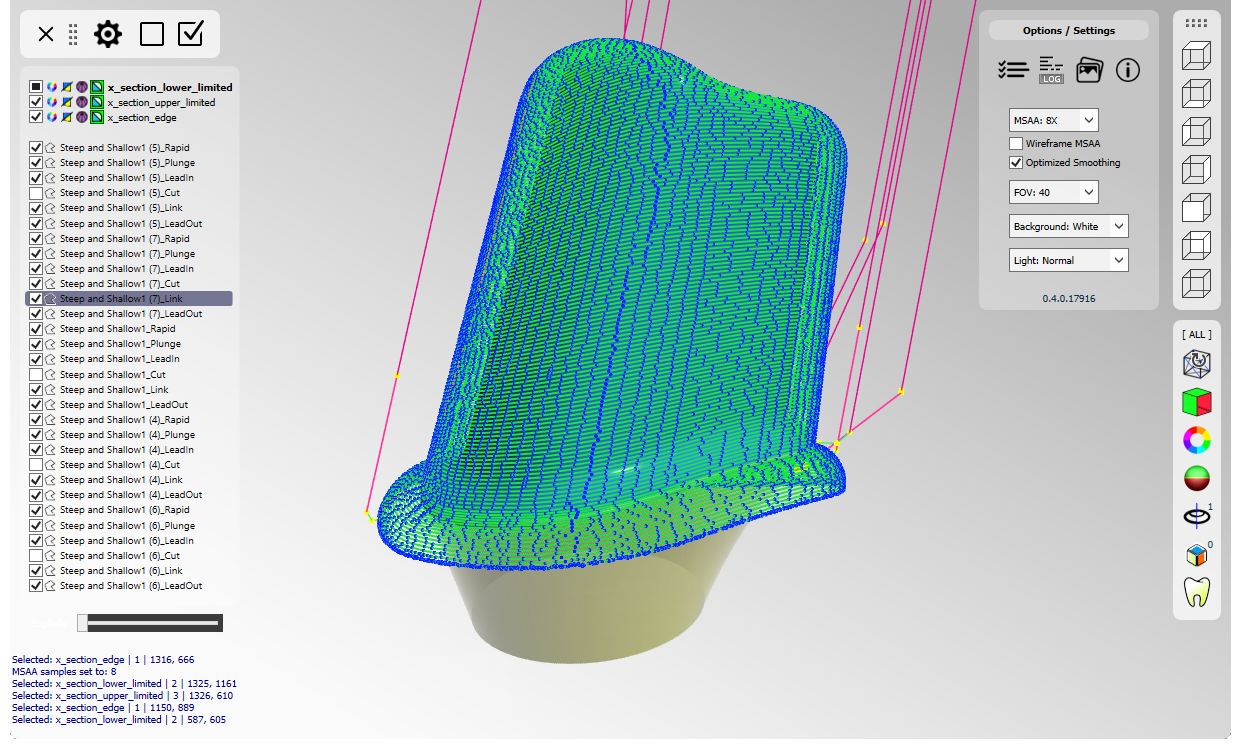

Strategy → toolpaths → G-code → nesting. Strategy selection + governed execution as part of the manufacturing plan, built on an in-house 3D engine and dental-specific mesh handling.

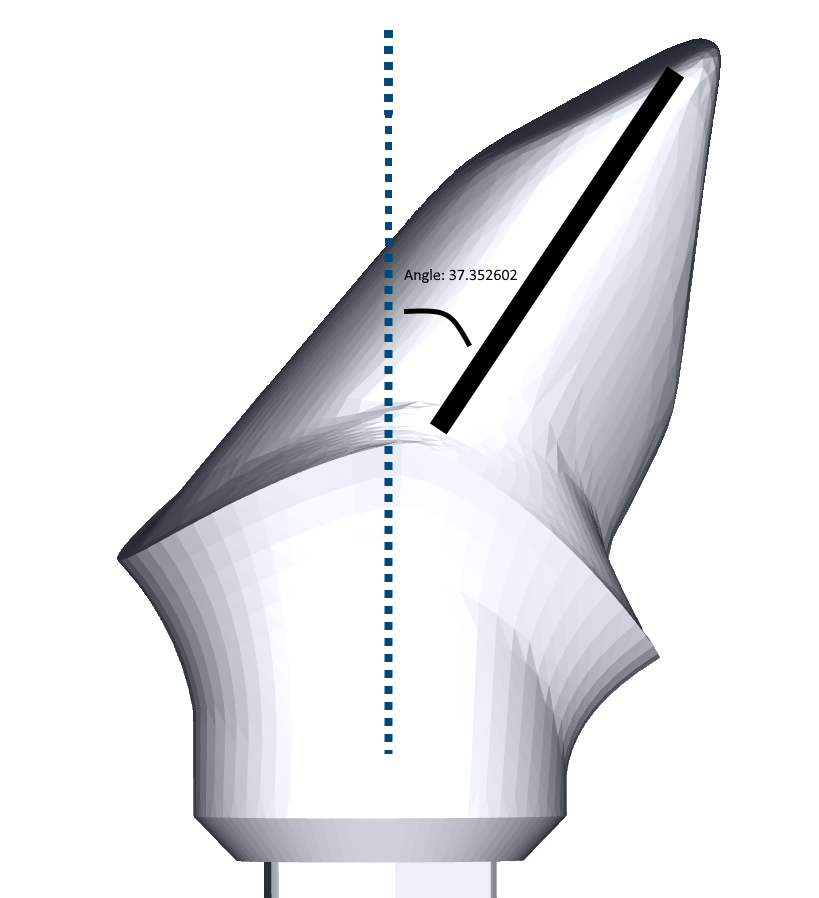

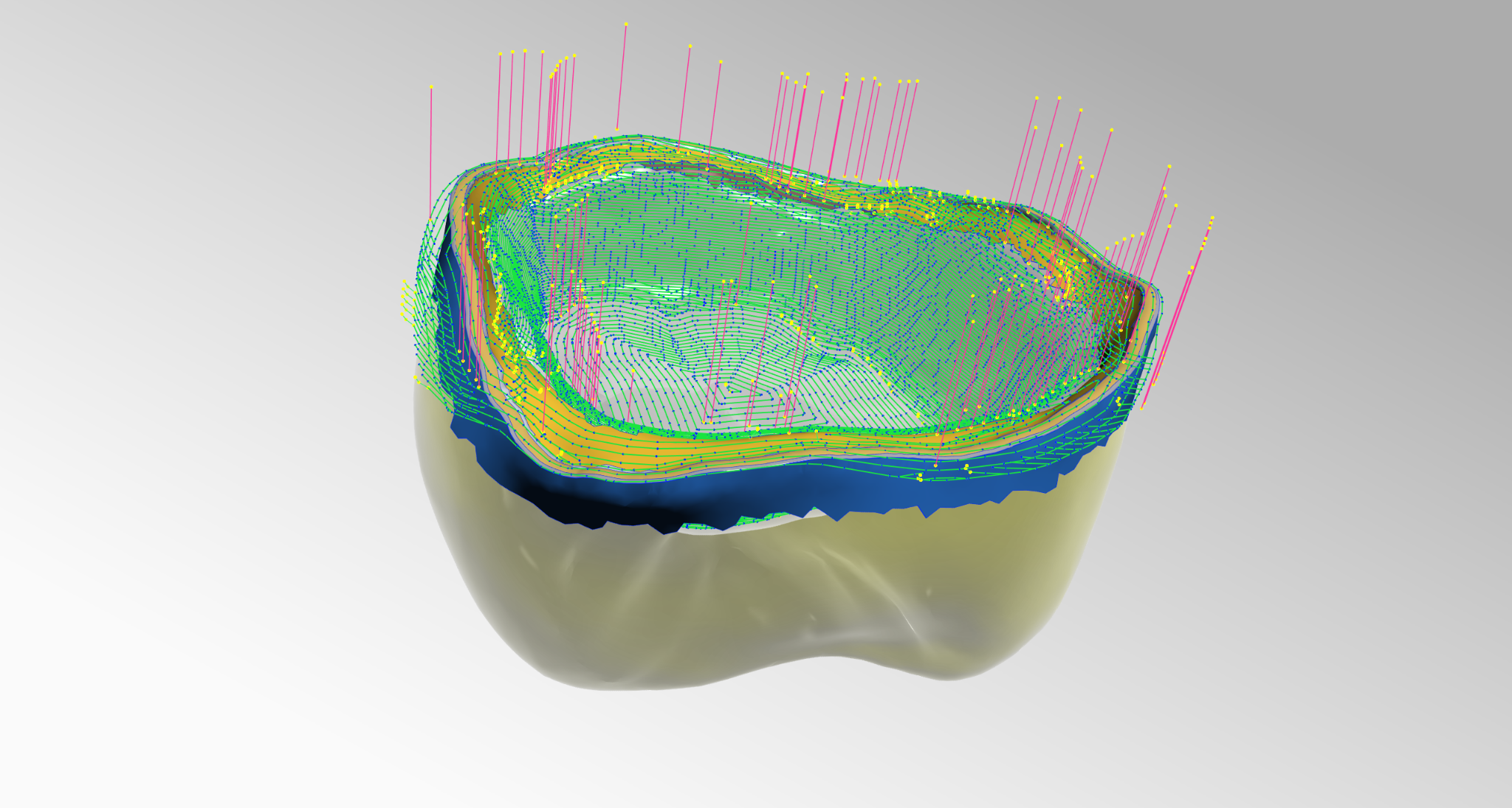

Analyze the new case and generate reports automatically. Analysis includes Smart Abutment Body Angle, Overall Body Thickness, Margin Thickness, Dimensions, and Mesh artifacts.

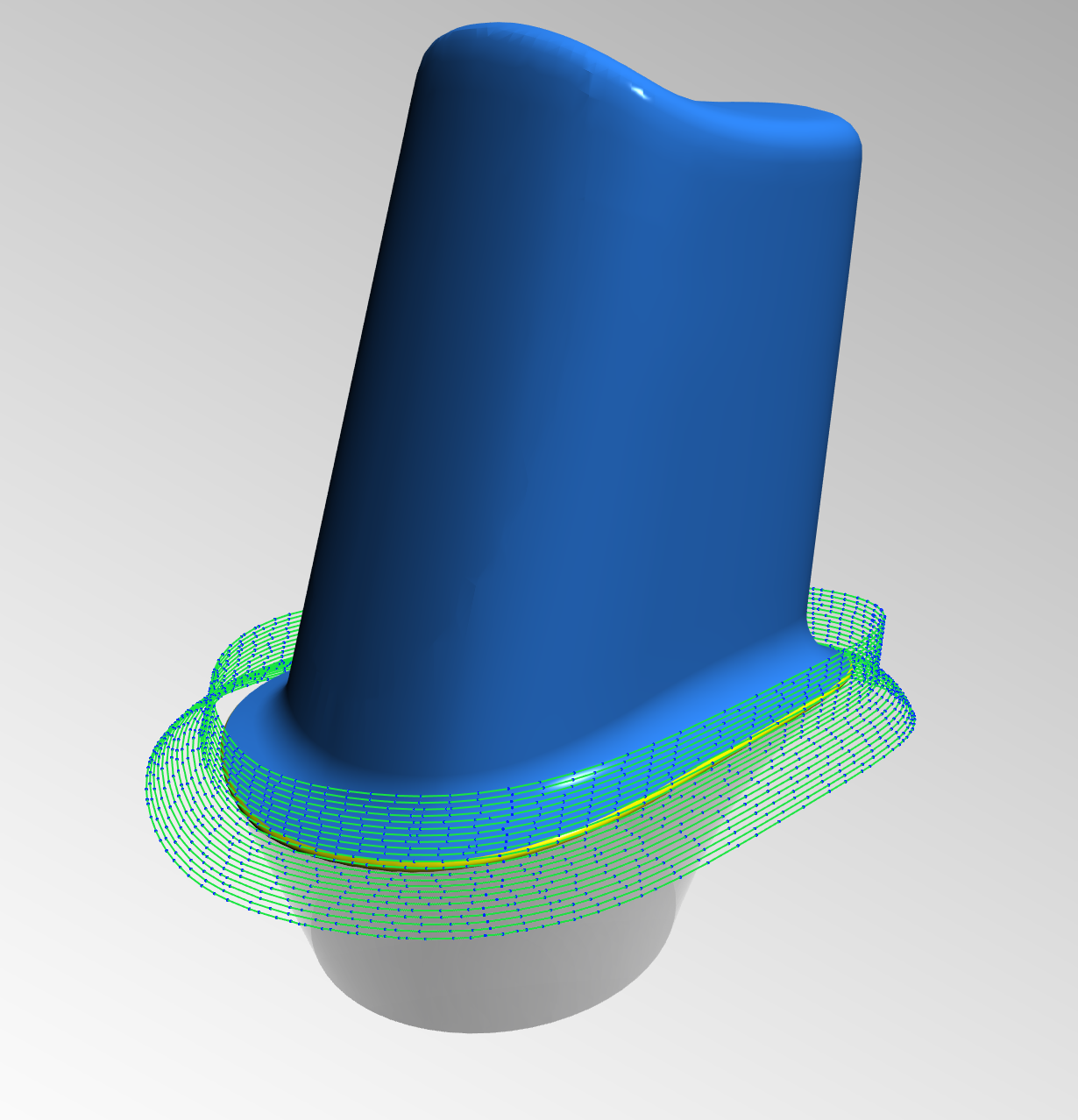

Optimization includes abutment margin edge rounding, mesh undercuts, mesh artifact smoothing, and geometry sections for precise downstream control.

Apply toolpath strategies based on geometry analysis and sectioning, calculate G-code, and determine nesting requirements.

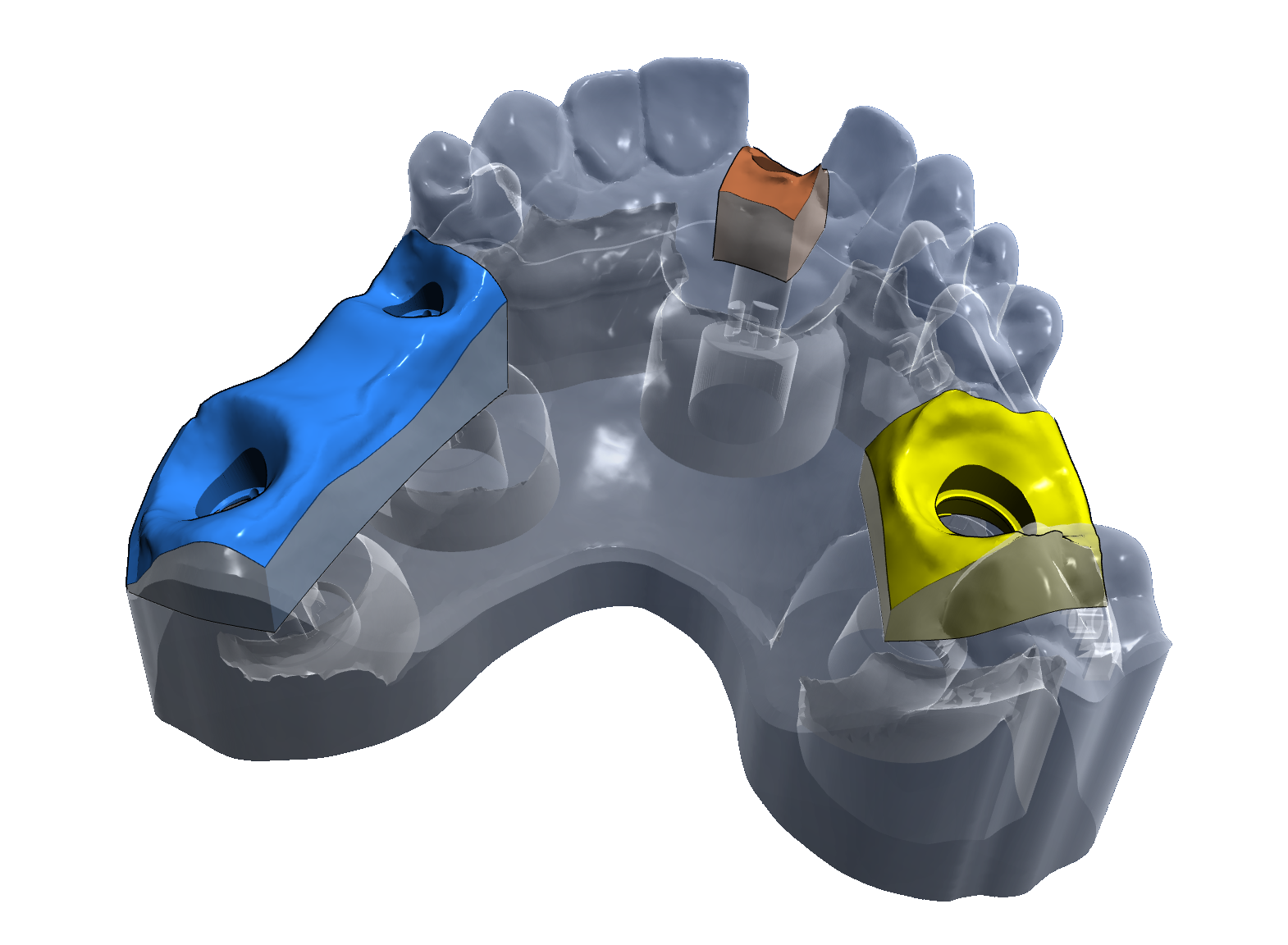

Analysis includes Margin Thickness, Margin Band Inner/Outer Bounds, Overall Body Thickness, and geometry constraints in critical areas.

Optimization includes margin correction and wall-thickness correction to optimize for manufacturing and mitigate scrap.

Apply toolpath strategies based on geometry analysis and sectioning, calculate G-code, and determine nesting requirements (CAM now, nest & post later).

DentSolv is a cloud-native manufacturing optimization layer (Design → Optimize → Execute) that connects design output to real manufacturing constraints at scale.

Every new case is analyzed in seconds with manufacturing strategy in mind—so labs and milling centers move from design intent to production-ready output with fewer surprises.

Manufacturing-first CAD/CAM intelligence: checks angles, thickness, margins, dimensions, and mesh artifacts so designs ship ready for production—not discovered late in QC.

Custom dental 3D engine + proprietary mesh stack provide deterministic geometry optimization (undercuts, artifact smoothing, margin handling, controlled sectioning) and reliable feature deconstruction/splitting.

Execution intelligence + governed automation (where others stop): strategy selection driven by geometry/sections, plus G-code + nesting requirements via an Automation IDE and execution engine.

DentSolv is delivered as a cloud-native platform to unlock value quickly—lower cost of ownership, highly scalable infrastructure, and the fastest time-to-value with low IT overhead.

DentSolv supports a "prepare here, manufacture there" model—centralized preparation and validation can drive consistent output across remote manufacturing sites while keeping automation governed and auditable.

Founder

Founder

Founder

Fewer production failures, less waste/rework, and shorter lead times. Request a full technical walkthrough.

Contact / Book a Demo